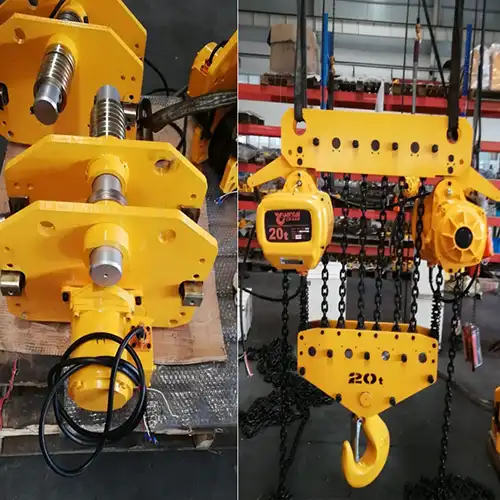

Hook Mounted Portable Electric Chain Block 20 Ton 50M Lifting Height

Portable electric chain hoist 20 ton 50m lifting height for efficient, powerful & verstile hoisting solution in various sites, portable hook chain hoist!

Category: Electric Chain Hoist Crane

Your Trusted Electric Chain Hoist Manufacturer & Supplier

Hook Mounted Portable Electric Chain Block 20 Ton 50M Lifting Height

Portable electric chain hoist 20 ton 50m lifting height for efficient, powerful & verstile hoisting solution in various sites, portable hook chain hoist!

Overview of 20 Ton Electric Chain Hoists with Portable Hoist Design

When it comes to handling heavy loads, the Hook Mounted Portable 20 Ton Electric Chain Hoist stands tall. With its impressive capacity and versatile design, it's the go-to solution for lifting tasks that demand precision and power. Whether it's construction, manufacturing, or logistics, this hoist is a trusted companion in getting the job done efficiently.

Key Features:

- Capacity: With a whopping 20-ton capacity, this electric chain hoist is built to handle even the heaviest of loads with ease. From large machinery to building materials, it's equipped to lift and move substantial weights effortlessly.

- Lifting Height: Going the distance is no challenge for this hoist, thanks to its impressive lifting height of 50 meters. Whether you need to reach great heights in construction or navigate tall shelves in a warehouse, this hoist has got you covered.

- Power Supply: Operating at 380V, 50Hz, 3-phase power supply, this hoist ensures consistent and reliable performance. With its robust power system, it delivers the necessary force to tackle demanding lifting tasks without breaking a sweat.

As we delve deeper into the world of electric chain hoists, we'll explore how these key features translate into real-world applications and the advantages they offer in various industries. Stay tuned as we uncover the versatility, safety, and efficiency of the 20 Ton Electric Chain Hoist.

Exploring the Features of the 20 Ton Electric Chain Hoist

When it comes to heavy lifting, having the right tools can make all the difference. The 20 Ton Electric Chain Hoist is packed with features that not only streamline operations but also enhance safety and versatility. Let's take a closer look at what sets this hoist apart from the rest.

- Portable Electric Chain Hoist: Gone are the days of being tethered to a single location. With its portable design, this electric chain hoist offers unparalleled mobility, allowing you to tackle lifting tasks wherever they arise. Whether it's a construction site, manufacturing facility, or warehouse, you can count on this hoist to follow you wherever the job takes you.

- Hook Mounted Design: Versatility is key in any lifting operation, and the hook-mounted design of this hoist delivers just that. With its easily attachable hook, you can secure the hoist to a variety of anchor points, making it suitable for a wide range of applications. From beams to scaffolding, this hoist adapts to your needs, ensuring maximum flexibility and efficiency.

- Flexibility for Wide Applications: No two lifting tasks are the same, which is why versatility is essential. Whether you're lifting heavy machinery in a manufacturing plant or hoisting building materials on a construction site, this hoist is up to the challenge. Its flexible design allows for seamless integration into diverse work environments, making it a valuable asset across industries.

- Reliability for Vertical Hoisting: When it comes to vertical lifting, reliability is non-negotiable. With its robust construction and advanced features, this hoist offers unparalleled reliability, ensuring smooth and safe vertical hoisting operations. Whether you're lifting loads to great heights or lowering them with precision, you can trust this hoist to get the job done safely and efficiently.

As we explore the features of the 20 Ton Electric Chain Hoist, it becomes clear why it's the preferred choice for heavy lifting tasks. From its portable design to its reliability for vertical hoisting, this hoist is a testament to innovation and efficiency in the world of lifting equipment.

Portable electric chian hoist 20 ton for sale

Hook mounted portable electric chain hoist 20 ton with 50 meters lifting height, customized design

Electric chain fall hoist, chain bag

20 ton electric hoist packed into wooden cases for delivery to ensure chain hoist safety

The Advantages of Hook Mounted Portable Electric Chain Hoists

In today's busy work environments, adaptability and mobility are key factors in achieving efficiency and productivity. The hook-mounted portable electric chain hoist offers a multitude of advantages that empower workers to tackle lifting tasks with ease. Let's explore how its unique features translate into tangible benefits for businesses across industries.

Enhanced Mobility:

- Easy Relocation and Installation: The hook-mounted design of this electric chain hoist facilitates seamless relocation and installation across various work sites. Whether you're moving from one end of a construction site to another or transitioning between different areas within a manufacturing facility, this hoist makes the process effortless. Its lightweight and compact construction ensure hassle-free transportation, allowing workers to set up quickly and get to work without delay.

- Suitable for Frequent Load Movements: In dynamic work environments where lifting tasks are frequent and varied, the ability to quickly and easily move loads is invaluable. The hook-mounted portable electric chain hoist excels in such scenarios, offering unparalleled flexibility and efficiency. Whether you're lifting materials onto scaffolding, positioning machinery in a manufacturing plant, or loading cargo onto shelves in a warehouse, this hoist enables smooth and swift load movements. Its versatile hook attachment allows for secure anchoring to a variety of structures, ensuring stability and safety during operation.

As businesses strive to optimize their operations and maximize productivity, the advantages offered by hook-mounted portable electric chain hoists become increasingly apparent. From simplified relocation and installation to seamless load movements, these hoists empower workers to accomplish lifting tasks with precision and efficiency, ultimately driving business success. Stay tuned as we delve deeper into the benefits of this indispensable tool and uncover its impact on various industries.

Versatility:

When it comes to lifting equipment, versatility is paramount. The hook-mounted portable electric chain hoist epitomizes adaptability, making it an indispensable tool for a wide range of applications. Let's explore how its versatility sets it apart and makes it the go-to solution for lifting tasks in diverse environments.

- Adaptable to Diverse Environments and Lifting Requirements: One of the standout features of the hook-mounted portable electric chain hoist is its ability to adapt to various environments and meet diverse lifting requirements. Whether you're working in a construction site, manufacturing facility, or warehouse, this hoist proves its versatility time and time again. Its flexible design allows it to seamlessly integrate into different work settings, ensuring that lifting tasks are completed efficiently and safely. From heavy machinery to building materials, this hoist can handle it all with ease, making it a valuable asset across industries.

- Ideal for Confined Spaces or Areas with Limited Access: In environments where space is limited and access is restricted, traditional lifting equipment may struggle to maneuver effectively. However, the hook-mounted portable electric chain hoist excels in such conditions, thanks to its compact and maneuverable design. Whether you're navigating tight spaces in a construction site or working within confined areas in a warehouse, this hoist offers unmatched versatility. Its ability to operate efficiently in challenging environments ensures that lifting tasks can be completed with precision, even in the most constrained spaces.

As businesses face ever-changing demands and environments, the versatility of the hook-mounted portable electric chain hoist becomes increasingly invaluable. From its adaptability to diverse environments to its effectiveness in confined spaces, this hoist proves to be a versatile and reliable solution for a wide range of lifting tasks. Stay tuned as we continue to explore the myriad benefits of this essential tool and its impact on lifting operations across industries.

Safety:

Safety is paramount in any workplace, especially when it comes to heavy lifting operations. The hook-mounted portable electric chain hoist is designed with safety as a top priority, providing peace of mind for workers and employers alike. Let's delve into how this hoist ensures a safe working environment.

- Secure Attachment to the Load Reduces Risks of Accidents: The hook-mounted design of this electric chain hoist ensures a secure attachment to the load, significantly reducing the risk of accidents during lifting operations. Whether lifting heavy machinery, construction materials, or industrial equipment, the hoist's robust hook attachment provides a reliable anchor point, preventing unexpected dislodgement or slippage. This secure attachment not only protects the load from damage but also safeguards surrounding workers and property from potential hazards, ensuring a safe and controlled lifting process.

- Minimizes Manual Handling, Promoting Worker Safety: Manual handling of heavy loads poses significant risks to worker safety, including musculoskeletal injuries and accidents. The hook-mounted portable electric chain hoist minimizes these risks by eliminating the need for manual lifting and positioning of heavy loads. With its motorized operation and ergonomic controls, workers can safely and efficiently maneuver loads with minimal physical exertion. This not only reduces the likelihood of injuries but also enhances overall productivity by allowing workers to focus on more critical tasks without compromising their safety.

In today's fast-paced work environments, ensuring the safety of workers and equipment is non-negotiable. The hook-mounted portable electric chain hoist provides a reliable solution, offering secure load attachment and minimizing manual handling risks. With safety at the forefront of its design, this hoist empowers workers to perform lifting tasks with confidence and efficiency, ultimately fostering a safer and more productive workplace environment. Stay tuned as we continue to explore the benefits of this essential tool and its impact on workplace safety.

Comparison: Trolley Mounted vs. Hook Mounted 20 Ton Electric Chain Hoists

In heavy lifting, selecting the right equipment can make all the difference in productivity and efficiency. When it comes to 20-ton electric chain hoists, two primary options stand out: trolley mounted and hook mounted. Let's compare these two configurations to understand their respective strengths and applications.

Trolley Mounted Electric Chain Hoists:

Trolley mounted electric chain hoists offer a unique set of advantages tailored to specific lifting requirements. Here's what sets them apart:

- Horizontal Mobility along Tracks or Beams: Unlike their hook-mounted counterparts, trolley mounted hoists feature a trolley mechanism that allows horizontal movement along tracks or beams. This mobility enables precise positioning of loads across a horizontal plane, making them ideal for applications where lateral movement is essential.

- Suited for Applications Requiring Lateral Movement of Loads: Industries such as manufacturing and logistics often require the lateral movement of heavy loads within a workspace. Trolley mounted electric chain hoists excel in such scenarios, providing the flexibility to traverse horizontally along designated tracks or beams. Whether it's moving materials along assembly lines or positioning cargo in storage facilities, these hoists offer unmatched versatility.

- Provides Flexibility in Positioning Heavy Loads within a Workspace: The ability to position heavy loads with precision is crucial in optimizing workflow and maximizing efficiency. Trolley mounted electric chain hoists offer precisely that, allowing operators to maneuver loads horizontally to their desired locations. This flexibility in positioning ensures that materials can be placed precisely where needed, minimizing downtime and streamlining operations.

In summary, trolley mounted electric chain hoists are well-suited for applications that require horizontal mobility and precise positioning of heavy loads within a workspace. Their ability to traverse along tracks or beams makes them indispensable tools in industries where lateral movement is essential for efficient operations. Stay tuned as we explore the advantages of hook mounted electric chain hoists in the next section.

Model | Item | Motortized travelling Electric Chain Hoist | ||||||||||

Capacity | ton | 0.5 | 1 | 1 | 2 | 2 | 3 | 3 | 5 | 7.5 | 10 | 20 |

Standard Lifting Height | m | 3 | ||||||||||

Lifting Speed | m/min | 7.8 | 6.8 | 3.9 | 6.8 | 3.4 | 5.6 | 3.4 | 2.8 | 1.8 | 2.7 | 1.3 |

Lifting motor | Power kw | 0.75 | 1.5 | 0.75 | 3 | 1.5 | 3 | 3 | 3 | 3 | 32 | 32 |

Rotation Speed r/min | 1440 | |||||||||||

Phase | 3 | |||||||||||

Voltage | 220-440 | |||||||||||

Frequency | 50/60 | |||||||||||

Travelling Motor | Power kw | 0.12 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.75 | 0.75 | 0.75 | 0.752 |

Rotation Speed r/min | 1440 | |||||||||||

Travelling Speed m/min | 12.2 | 10/20 | 10/20 | 10/20 | 10/20 | 10/20 | 10/20 | 10/20 | 10/20 | 10/20 | 10/20 | |

Phase | 3 | |||||||||||

Voltage | 220-440 | |||||||||||

Frequency | 50/60 | |||||||||||

No.of Chain Falls |

| 1 | 1 | 2 | 1 | 2 | 1 | 2 | 2 | 3 | 4 | 8 |

Chain Dia. | mm | 6.3 | 7.1 | 6.3 | 10 | 7.1 | 11.2 | 10 | 11.2 | 11.2 | 11.2 | 11.2 |

Test Load | ton | 0.625 | 1.25 | 1.25 | 2.5 | 2.5 | 3.75 | 3.75 | 6.25 | 9.375 | 12.5 | 25 |

I-beam | mm | 58-13 | 100-160 | 110-160 | 82-178 | 120-160 | 110-180 | 120-180 | 120-180 | 128-180 | 110-180 | 130-180 |

Hook Mounted Electric Chain Hoists:

When it comes to vertical lifting applications, hook-mounted electric chain hoists offer a range of benefits that cater to specific operational needs. Let's delve into the advantages that set them apart:

- Provides Vertical Lifting Capabilities without Lateral Movement: Unlike trolley-mounted hoists, which excel in horizontal mobility, hook-mounted electric chain hoists focus on vertical lifting operations. With their robust hook attachment, these hoists are optimized for lifting heavy loads straight up and down, making them ideal for applications where vertical movement is the primary requirement.

- More Compact and Maneuverable Than Trolley-Mounted Hoists: One of the key advantages of hook-mounted electric chain hoists is their compact and maneuverable design. Without the additional trolley mechanism, these hoists are lighter and more streamlined, making them easier to maneuver in tight spaces and confined environments. Their smaller footprint allows for greater flexibility in installation and operation, particularly in areas where space is limited.

- Ideal for Vertical Hoisting Applications with Minimal Horizontal Mobility Requirements: In industries where vertical lifting is the primary focus and horizontal movement is minimal, hook-mounted electric chain hoists shine. Whether it's lifting heavy machinery in a manufacturing plant or hoisting materials to upper floors in a construction site, these hoists offer unmatched reliability and efficiency in vertical hoisting operations. Their simplicity and focused design make them the preferred choice for applications where vertical movement is paramount.

In conclusion, hook-mounted electric chain hoists are tailored for vertical lifting applications where precision and reliability are essential. With their vertical lifting capabilities, compact design, and suitability for confined spaces, these hoists are indispensable tools in industries where vertical movement takes precedence. Stay tuned as we compare the overall performance and suitability of both trolley-mounted and hook-mounted electric chain hoists in our final analysis.

| Model | Item | Hook Mounted Electric Chain Hoists Specifications | ||||||

| Capacity | ton | 7.5 Ton | 10 Ton | 15 Ton | 20 Ton | 25 Ton | 30 Ton | 35 Ton |

| Standard Lifting Height | m | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Lifting Speed | m/min | 1.8 | 2.8 | 1.9 | 1.4 | 1.1 | 0.9 | 0.7 |

| Lifting motor | Power kw | 3 | 32 | 32 | 32 | 32 | 32 | 32 |

| Rotation Speed r/min | 1440 | |||||||

| Phase | 3 | |||||||

| Voltage | 220-440 | |||||||

| Frequency | 50/60 | |||||||

| Travelling Motor | Power kw | 0.75 | 0.75 | 0.752 | 0.752 | 0.752 | 0.752 | 0.752 |

| Rotation Speed r/min | 1440 | |||||||

| Travelling Speed m/min | 10 | |||||||

| Phase | 3 | |||||||

| Voltage | 220-440 | |||||||

| Frequency | 50/60 | |||||||

| No.of Chain Falls | 3 | 4 | 6 | 8 | 10 | 12 | 16 | |

| Chain Dia. | mm | 11.2 | 11.2 | 11.2 | 11.2 | 11.2 | 11.2 | 11.2 |

| Test Load | ton | 9.375 | 12.5 | 18.75 | 25 | 31.25 | 37.5 | 43.75 |

| I-beam | mm | 120-180 | 180-202 | 150-220 | 150-220 | 150-220 | 150-220 | 150-220 |

Typical Applications for Vertical Material Handling

Vertical material handling plays a crucial role in various industries, facilitating the movement of heavy loads to different elevations with precision and efficiency. Let's explore some typical applications of vertical material handling, starting with the construction industry:

Construction Industry:

- Lifting Steel Beams, Prefabricated Structures, and Building Materials: In construction projects, the need to lift heavy materials to elevated positions is a common occurrence. Whether it's steel beams for structural support, prefabricated components for building assemblies, or construction materials like concrete blocks and bricks, vertical material handling equipment, such as electric chain hoists, is indispensable. Hook-mounted electric chain hoists excel in lifting these heavy loads vertically, ensuring safe and efficient placement at various levels of construction projects.

- Hoisting Heavy Machinery or Equipment to Upper Floors: Construction sites often require the installation of heavy machinery and equipment on upper floors of buildings or structures. This could include items such as HVAC systems, generators, or large-scale construction machinery. Hook-mounted electric chain hoists provide the necessary lifting capabilities to hoist these heavy loads vertically with precision and control. Their reliability and safety features make them the preferred choice for lifting valuable equipment to higher elevations, minimizing the risk of damage and ensuring smooth construction operations.

In the dynamic and demanding environment of the construction industry, vertical material handling equipment plays a vital role in streamlining operations and enhancing productivity. Hook-mounted electric chain hoists offer a reliable solution for lifting heavy loads vertically, enabling construction projects to proceed efficiently and safely. Stay tuned as we explore additional typical applications of vertical material handling in other industries.

Manufacturing Sector:

In the manufacturing sector, the efficient movement of materials and equipment is essential for optimizing production processes and ensuring smooth operations. Vertical material handling equipment, such as hook-mounted electric chain hoists, plays a crucial role in facilitating these tasks. Let's explore some typical applications of vertical material handling in the manufacturing industry:

- Moving Large Components or Assemblies Within Facilities: Manufacturing facilities often deal with large components or assemblies that need to be transported within the premises. These components may include machine parts, structural frames, or finished products. Vertical material handling equipment, such as hook-mounted electric chain hoists, provides the necessary lifting capabilities to move these heavy loads vertically with ease. Whether it's transferring components between workstations or transporting finished products for packaging and shipping, electric chain hoists offer a reliable and efficient solution for internal material movement within manufacturing facilities.

- Installing and Positioning Heavy Machinery or Industrial Tools: Manufacturing processes frequently require the installation and positioning of heavy machinery or industrial tools. This could involve setting up production lines, installing conveyor systems, or positioning specialized equipment for manufacturing operations. Hook-mounted electric chain hoists provide the lifting power and precision needed to hoist heavy machinery and position it accurately at desired locations. Their compact and maneuverable design allows for precise placement of equipment within the manufacturing facility, optimizing workflow and maximizing operational efficiency.

In the fast-paced and demanding environment of the manufacturing sector, vertical material handling equipment is instrumental in maintaining efficiency and productivity. Hook-mounted electric chain hoists offer a versatile and reliable solution for moving heavy loads vertically, enabling manufacturers to streamline their operations and meet production targets effectively. Stay tuned as we explore additional typical applications of vertical material handling in other industries.

Warehousing and Logistics:

Efficient warehousing and logistics operations rely on the seamless movement of goods, both vertically and horizontally, within distribution centers and storage facilities. Vertical material handling equipment, such as hook-mounted electric chain hoists, plays a critical role in facilitating these tasks. Let's explore some typical applications of vertical material handling in the warehousing and logistics sector:

- Loading and Unloading Cargo onto High Shelves or Racks: Warehouses and distribution centers often utilize vertical storage solutions, such as high shelves or racks, to maximize storage capacity and floor space. Loading and unloading cargo onto these elevated storage structures require specialized equipment capable of lifting heavy loads vertically. Hook-mounted electric chain hoists provide the lifting power and precision needed to move goods from ground level to high shelves or racks with ease. Whether it's palletized goods, containers, or bulky items, electric chain hoists enable efficient vertical movement, optimizing storage space and ensuring timely access to inventory.

- Handling Palletized Goods or Containers in Distribution Centers: Distribution centers play a crucial role in the supply chain, serving as hubs for receiving, storing, and distributing goods to various destinations. Efficient handling of palletized goods and containers within distribution centers is essential for maintaining smooth operations and meeting customer demands. Hook-mounted electric chain hoists offer a versatile solution for lifting and maneuvering palletized goods and containers vertically within distribution centers. Whether it's transferring goods from loading docks to storage areas or preparing shipments for outbound transportation, electric chain hoists streamline the handling process, reducing labor costs and improving operational efficiency.

In the dynamic and fast-paced environment of warehousing and logistics, vertical material handling equipment is instrumental in optimizing storage and distribution processes. Hook-mounted electric chain hoists provide a reliable and efficient solution for lifting and maneuvering goods vertically, enabling warehouses and distribution centers to operate smoothly and meet the demands of modern supply chains. Stay tuned as we explore additional typical applications of vertical material handling in other industries.

Related Topics and Concerned Questions on Electric Powered Portable Chain Hoists

As with any industrial equipment, safety is paramount when operating electric powered portable chain hoists. Let's delve into some related topics and address concerned questions regarding safety measures:

Safety Measures:

Recommended Protocols for Operating Electric Chain Hoists Safely:

Operating electric chain hoists safely requires adherence to recommended protocols and best practices. Some key safety measures include:

Conducting thorough pre-operation inspections to ensure the hoist is in proper working condition.

Following manufacturer's instructions and guidelines for hoist operation, including load capacity limits and lifting procedures.

Properly securing and attaching loads to the hoist's hook to prevent slippage or dislodgement during lifting.

Using appropriate personal protective equipment (PPE), such as gloves and safety glasses, when handling loads or operating the hoist.

Avoiding exceeding the hoist's rated capacity and avoiding side-loading or improper rigging configurations.

Ensuring adequate training and certification for operators to operate the hoist safely and effectively.

Regularly inspecting and maintaining the hoist to identify and address any potential issues or defects that could compromise safety.

Mitigation of Potential Hazards Associated with Hoist Usage:

While electric chain hoists are designed with safety features to minimize risks, certain hazards can still arise during operation. It's essential to implement mitigation strategies to address these potential hazards effectively. Some common hazards associated with hoist usage and their mitigation measures include:

- Overloading: Ensure operators are aware of the hoist's rated capacity and do not exceed it. Implement load monitoring systems and use load indicating devices to prevent overloading.

Electrical Hazards: Inspect power cords, plugs, and connections for damage before use. Use ground fault circuit interrupters (GFCIs) and ensure proper grounding to prevent electrical shocks.

Falls and Struck-By Incidents: Implement proper fall protection measures, such as guardrails and safety harnesses, when working at heights. Use barricades or warning signs to prevent unauthorized personnel from entering the hoisting area.

Pinch Points and Crush Hazards: Ensure proper clearance around the hoist's moving parts to prevent entrapment or crush injuries. Use warning labels and safety barriers to identify and mitigate pinch points.

Environmental Hazards: Consider environmental factors such as weather conditions and temperature extremes that could affect hoist operation. Implement appropriate measures, such as shielding or insulation, to protect the hoist from environmental hazards.

By addressing these safety measures and mitigation strategies, operators can minimize risks and ensure the safe operation of electric powered portable chain hoists in various industrial settings. Stay tuned as we explore additional related topics and address concerned questions regarding hoist operation and maintenance.

Maintenance Requirements:

Ensuring the optimal performance and longevity of electric powered portable chain hoists necessitates diligent maintenance and regular inspections. Here, we outline essential maintenance procedures and recommended inspection intervals to keep these hoists in top working condition.

Procedures for Ensuring Optimal Performance and Longevity:

Regular maintenance is crucial for the reliable operation of electric chain hoists. The following procedures help ensure optimal performance and extend the lifespan of the equipment:

Lubrication: Regularly lubricate the chain and moving parts to reduce friction and wear. Use manufacturer-recommended lubricants to ensure compatibility and effectiveness.

Cleaning: Keep the hoist clean and free of dust, dirt, and debris. Wipe down the hoist after each use and cover it when not in operation to prevent contamination.

Chain Inspection: Inspect the chain for signs of wear, corrosion, or damage. Replace any worn or damaged links to maintain the integrity and safety of the lifting mechanism.

Hook and Latch Check: Examine the hook and latch mechanism for any signs of deformation, cracks, or wear. Ensure the latch closes securely and replace any defective components.

Electrical Components: Regularly check the electrical system, including cables, connectors, and controls, for any signs of damage or wear. Ensure all connections are secure and replace damaged parts as needed.

Brake System: Test the brake system to ensure it engages and releases correctly. Adjust or replace the brake pads if they show signs of excessive wear.

Load Testing: Periodically perform load tests to verify the hoist's lifting capacity and performance. Follow manufacturer guidelines for conducting load tests safely.

Recommended Inspection Intervals for Maintenance Checks:

Regular inspections are vital for early detection of potential issues and preventing equipment failure. Here are the recommended inspection intervals for maintenance checks:

Daily Inspections: Conduct a visual inspection before each use. Check for any obvious signs of wear, damage, or malfunction, such as frayed cables, worn chains, and loose components.

Weekly Inspections: Perform a more thorough inspection at least once a week. This includes checking the lubrication of moving parts, inspecting the hook and latch mechanism, and testing the brake system.

Monthly Inspections: Conduct a comprehensive inspection monthly. This should include detailed checks of the chain, electrical components, and load-bearing structures. Replace any worn or damaged parts as necessary.

Quarterly Inspections: Every three months, carry out an extensive inspection that includes load testing and a full assessment of the hoist's overall condition. Document any maintenance performed and any parts replaced.

Annual Inspections: Annually, have a qualified technician perform a complete overhaul of the hoist. This should include a detailed inspection of all components, load testing, and any necessary repairs or replacements.

By adhering to these maintenance procedures and inspection intervals, operators can ensure the safe and efficient operation of electric powered portable chain hoists. Regular maintenance not only extends the lifespan of the equipment but also enhances safety and reliability in lifting operations. Stay tuned as we continue to explore additional topics and answer common questions about electric chain hoists.

Load Capacity and Limitations:

Understanding the load capacity and limitations of electric powered portable chain hoists is crucial for selecting the right equipment for specific applications and ensuring safe operation. Let's explore how load capacities compare across different hoist models and the factors influencing maximum load capacity.

Comparison of Load Capacities Between Different Hoist Models:

Electric chain hoists come in various models, each designed to handle different load capacities. Here's a comparison of typical load capacities for different hoist models:

Light-Duty Hoists: These are designed for smaller loads, typically ranging from 0.5 ton to 5 tons. They are ideal for tasks such as lifting smaller components, tools, or light materials in workshops and maintenance operations.

Medium-Duty Hoists: These models can handle loads between 5 tons and 10 tons. They are suitable for more demanding applications, including medium-sized machinery, construction materials, and manufacturing components.

Heavy-Duty Hoists: With load capacities ranging from 10 tons to 20 tons or more, heavy-duty hoists are built for industrial and construction applications requiring the lifting of very heavy loads, such as large machinery, steel beams, and bulk materials.

The 20-ton electric chain hoist, for example, falls into the heavy-duty category and is capable of handling substantial loads, making it ideal for demanding industrial and construction tasks.

Factors Influencing Maximum Load Capacity for Specific Applications:

Several factors can influence the maximum load capacity of a hoist in specific applications. Understanding these factors is essential for selecting the appropriate hoist and ensuring safe operation:

Load Type and Distribution: The nature of the load (e.g., uniform, concentrated, or uneven) can impact the hoist's capacity. Evenly distributed loads are easier to manage, while uneven or concentrated loads may require additional considerations to avoid overloading specific points.

Lift Height and Reach: The required lift height and horizontal reach can affect the hoist's effective load capacity. Higher lifts or extended reaches may reduce the hoist's ability to handle its maximum rated load due to increased stress on the equipment.

Environmental Conditions: Operating conditions, such as temperature, humidity, and exposure to corrosive substances, can impact the hoist's performance and load capacity. Harsh environments may require hoists with specialized coatings or materials to maintain their rated capacity.

Hoist Configuration and Accessories: The use of accessories like slings, spreader bars, and lifting beams can influence the load capacity. Proper configuration and selection of accessories are crucial to ensure the hoist operates within its rated limits.

Manufacturer Specifications: Always adhere to the manufacturer's specifications and guidelines for load capacities and operating conditions. Manufacturers provide detailed information on the maximum load capacity under various conditions, and it's essential to follow these guidelines to ensure safety and reliability.

By comparing load capacities between different hoist models and understanding the factors influencing maximum load capacity, operators can make informed decisions when selecting hoists for specific applications. This knowledge ensures that the chosen hoist meets the operational requirements while maintaining safety and efficiency in lifting operations. Stay tuned as we explore more related topics and address common concerns regarding electric powered portable chain hoists.

Power Supply and Compatibility:

The power supply is a crucial consideration when selecting and operating electric powered portable chain hoists. Ensuring compatibility with the available power sources and adapting to different voltages can significantly impact the hoist's performance and safety. Let's explore the standard power supply specifications for industrial settings and the options for adapting hoists to different power sources or voltages.

Standard Power Supply Specifications for Industrial Settings:

In industrial settings, the power supply specifications for electric hoists typically adhere to certain standards to ensure consistent and reliable operation. Common specifications include:

Voltage: Industrial electric hoists commonly operate on 380V, 50Hz, 3-phase power. This voltage standard is prevalent in many regions and provides the necessary power for heavy-duty lifting operations.

Frequency: The standard frequency for industrial power supplies is usually 50Hz, although some regions may use 60Hz. Ensuring the hoist's motor is compatible with the local frequency is essential for optimal performance.

Phase: Most industrial electric hoists require a 3-phase power supply, which provides balanced power distribution and efficient operation for high-capacity lifting tasks.

Options for Adapting Hoists to Different Power Sources or Voltages:

In some cases, the available power supply at a worksite may differ from the hoist's standard specifications. Adapting hoists to different power sources or voltages can be achieved through various methods:

- Transformers: Using a transformer can convert the available voltage to match the hoist's required voltage. For example, if the worksite provides 220V power, a transformer can step up the voltage to 380V, ensuring compatibility with the hoist.

Frequency Converters: If the local frequency differs from the hoist's requirement (e.g., 60Hz instead of 50Hz), a frequency converter can adjust the frequency to match the hoist's motor specifications. This ensures the motor operates smoothly and efficiently.

Phase Converters: In environments where only single-phase power is available, a phase converter can be used to convert single-phase power to three-phase power. This enables the operation of three-phase hoists in locations without a three-phase power supply.

Custom Motor Configurations: Some manufacturers offer custom motor configurations that can be tailored to specific voltage and frequency requirements. This allows the hoist to be directly compatible with the available power supply without the need for external converters.

Portable Power Solutions: For remote or off-grid locations, portable power solutions such as generators or battery packs can provide the necessary power for electric hoists. These solutions offer flexibility in powering hoists in various environments, ensuring continuous operation even in the absence of a stable power grid.

By understanding the standard power supply specifications for industrial settings and exploring options for adapting hoists to different power sources or voltages, operators can ensure the reliable and efficient operation of electric powered portable chain hoists in diverse environments. This adaptability enhances the hoist's versatility and broadens its range of applications, making it a valuable tool in various industrial and construction settings. Stay tuned as we explore more related topics and address common concerns regarding electric powered portable chain hoists.

Cost and ROI Analysis:

Investing in electric powered portable chain hoists involves considering the initial costs and the long-term benefits. Understanding the cost implications and the return on investment (ROI) can help businesses make informed decisions. Let's delve into the aspects of initial investment costs and how efficiency and productivity gains can justify these costs over time.

Initial Investment Costs for Purchasing and Installing Hoists:

The initial investment for electric chain hoists includes several components:

- Purchase Price: The cost of the hoist itself varies depending on the capacity, features, and brand. Heavy-duty hoists with higher capacities, such as a 20-ton model, generally have higher purchase prices.

Installation Costs: Installation involves setting up the hoist at the desired location, which may include mounting, electrical wiring, and any necessary structural modifications. These costs can vary based on the complexity of the installation and the site's existing infrastructure.

Accessories and Attachments: Additional accessories such as trolleys, slings, spreader bars, and remote control systems can enhance the hoist's functionality but add to the initial investment.

Training Costs: Ensuring that operators are adequately trained to use the hoist safely and efficiently may involve initial training costs. Investing in proper training helps maximize the hoist's performance and safety.

Efficiency and Productivity Gains Justify the Cost Over Time:

While the initial investment in electric chain hoists can be significant, the long-term benefits often justify the cost. Here's how efficiency and productivity gains contribute to a positive ROI:

- Increased Lifting Efficiency: Electric chain hoists significantly reduce the time and effort required to lift heavy loads compared to manual or less efficient lifting methods. This increased efficiency translates to faster operations and shorter project timelines.

Enhanced Worker Safety: By minimizing manual handling and reducing the risk of injuries, electric chain hoists contribute to a safer work environment. Fewer injuries mean less downtime and lower healthcare and compensation costs.

Improved Load Precision: Electric hoists offer precise control over lifting and positioning, which enhances the accuracy of load handling. This precision reduces the risk of damage to materials and equipment, leading to cost savings in repairs and replacements.

Versatility and Adaptability: The ability to handle a wide range of lifting tasks makes electric chain hoists versatile tools that can be used across various applications and industries. This adaptability maximizes the utilization of the hoist, improving the overall value of the investment.

Reduced Labor Costs: Automation of lifting tasks reduces the need for manual labor, allowing workers to focus on other critical tasks. This reduction in labor requirements can lead to significant cost savings over time.

Longevity and Durability: High-quality electric chain hoists are built to last, offering years of reliable service with proper maintenance. The long lifespan and consistent performance provide ongoing value, offsetting the initial investment.

By evaluating the initial investment costs and the long-term benefits, businesses can make informed decisions about investing in electric powered portable chain hoists. The efficiency and productivity gains, along with enhanced safety and versatility, often justify the cost, resulting in a positive ROI and contributing to the overall success and competitiveness of the business.

In conclusion, understanding the cost and ROI analysis of electric powered portable chain hoists helps businesses make strategic investments that enhance their operational capabilities. Stay tuned as we explore more related topics and address common concerns regarding electric chain hoists.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch